Detailed Inductors Classifications

Hi, everyone! For you guys who want to learn electronic components, it is very important for you guys to lay a basic foundation about components parts. Today I take you to know what is the inductor, its classification and application, and product part number. As well as its classification and application, and product part numbers.

What is inductor?

An inductor is a passive electronic component that stores energy in a magnetic field when an electric current flows through it. It is typically made of a coil of wire wound around a core material.

How inductors work?

The basic principle behind how an inductor works is Faraday's law of electromagnetic induction. When a current passes through the wire coil, a magnetic field is generated around it. This magnetic field induces a voltage in the coil, which opposes any changes in the current flowing through it.

In simpler terms, an inductor resists changes in current. When the current increases, the inductor generates a back electromotive force (EMF) that opposes the increase, thus storing energy in the magnetic field. Similarly, when the current decreases, the inductor releases the stored energy to maintain the current flow.

The strength of an inductor is measured by its inductance, which is determined by factors such as the number of turns in the coil, the core material, and the physical dimensions of the coil. Inductors are widely used in various electronic circuits for purposes like filtering, energy storage, and inductance matching.

*Based on Construction:

a. Wire-Wound Inductors: These are the most common type of inductors, constructed by winding a conductive wire around a core material.

b. Toroidal Inductors: These inductors have a toroidal-shaped core, which provides better magnetic coupling and low electromagnetic interference (EMI).

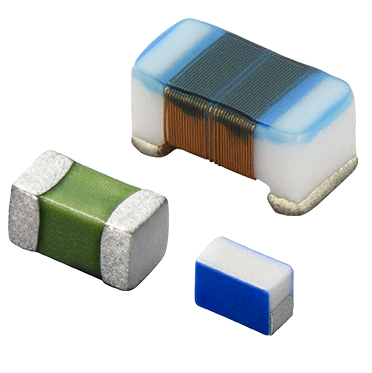

c. Multilayer Inductors: These are surface-mounted inductors constructed by layering multiple turns of wire or metal traces on a ceramic or PCB substrate.

d. Film Inductors: These inductors use a thin film of conductive material deposited on a non-conductive substrate.

e. Ferrite Bead Inductors: These are small cylindrical beads made of ferrite material, used to suppress high-frequency noise.

*Based on Core Material:

a. Air-Core Inductors: These inductors have no core material, and the inductance is primarily determined by the number of turns and the physical arrangement of the wire.

b. Iron-Core Inductors: These inductors have a core made of iron or iron alloys, which increases the inductance and magnetic field strength.

c. Ferrite-Core Inductors: These inductors use a core made of ferrite material, providing high permeability and excellent magnetic properties.

d. Powdered-Iron Core Inductors: These inductors use a powdered-iron core, which allows for flexibility in shaping and compact designs.

*Based on Purpose:

a. Power Inductors: These inductors are designed for high-current applications and are commonly used in power supplies, converters, and motor drives.

b. RF Inductors: These inductors are used in radio frequency (RF) circuits and are designed to have low parasitic capacitance and high self-resonant frequency.

c. Choke Inductors: These inductors are used to block or filter high-frequency signals and noise in power supplies and communication circuits.

d. Coupling Inductors: These inductors are used to transfer energy or signals between two circuits while providing isolation.

e. Tuning Inductors: These inductors are used in tuning circuits, such as radio receivers or filters, to adjust the resonance frequency.

*Based on Physical Form:

a. Through-Hole Inductors: These inductors have leads that are inserted through holes on a PCB for soldering.

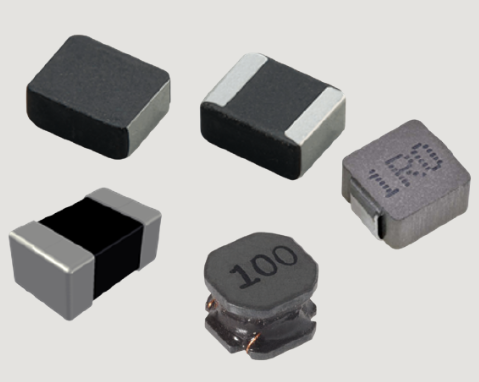

b. Surface-Mount Inductors: These inductors are designed for surface-mount technology (SMT) and are directly mounted on the surface of a PCB.